'Cheaper green hydrogen' | Electrolyser that uses supercritical water being developed with €3m of EU funding

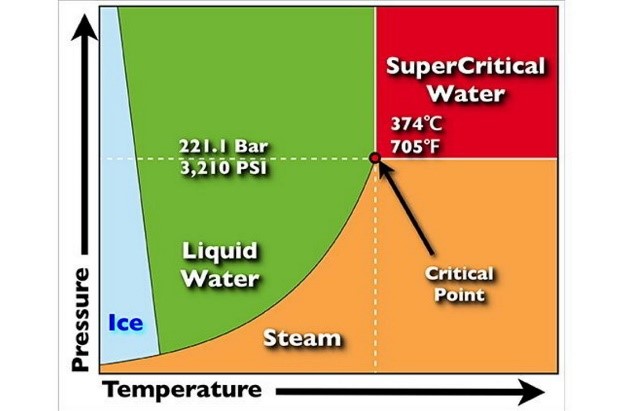

Industry news A groundbreaking electrolyser technology, utilizing supercritical water to generate green hydrogen, is in the developmental stages in Spain, backed by an allocation of nearly €3m ($3.24m) from the European Union (EU). The project, known as X-SEED (eXperimental Supercritical ElEctrolyser Development), is focused on splitting water molecules into hydrogen and oxygen under conditions of elevated temperature and pressure, leading to a supercritical state. In this state, above 374°C and pressures exceeding 221.1 bar, water exhibits characteristics of both a liquid and a gas.

A groundbreaking electrolyser technology, utilizing supercritical water to generate green hydrogen, is in the developmental stages in Spain, backed by an allocation of nearly €3m ($3.24m) from the European Union (EU). The project, known as X-SEED (eXperimental Supercritical ElEctrolyser Development), is focused on splitting water molecules into hydrogen and oxygen under conditions of elevated temperature and pressure, leading to a supercritical state. In this state, above 374°C and pressures exceeding 221.1 bar, water exhibits characteristics of both a liquid and a gas.

The consortium spearheading the development comprises diverse European entities, including companies, universities, and research institutions. They assert that this innovative technology maximizes energetic efficiency, enhances circularity, and prolongs the system's lifetime, thereby achieving a more competitive green hydrogen production process. A pivotal feature of the technology is its utilization of supercritical conditions and a membrane-less configuration, eliminating the need for membranes to separate hydrogen and oxygen molecules.

In laboratory demonstrations, a five-cell stack has been exhibited, featuring novel catalysts and electrodes that obviate the necessity for membranes. The consortium explains that supercritical conditions and the absence of membranes reduce the electrochemical work required for hydrogen generation, leading to increased system lifetime, improved voltage and energy efficiency (42kWh/kgH2), higher current density (>3A/cm2), enhanced hydrogen production rate, and robustness (degradation rate <1%/1000h).

Coordinated by the Spanish technology center Leitat, the X-SEED project has secured €2,989,495 from the EU's Horizon Europe fund for research and innovation, covering its entire expenses. Pau Bosch, the scientific coordinator of the project and principal investigator of the BioElectrochemical Systems group at Leitat, highlights the consortium's goal to develop a groundbreaking technology that economically competes in renewable hydrogen production. The project is slated to continue until the conclusion of June 2027.

Various other companies, such as Hysata, Stiesdal, Electrogenos, Hydrogen Systems Australia, and Electric Hydrogen, are also asserting the cost reduction potential of their innovative electrolyser technologies for green hydrogen production.